Increasing cost, busy shifts and spikes in shipment & production: The volatile nature of the intralogistics industry changes the pace of work on warehousing equipment and forklifts periodically and sometimes daily. For this reason, they need to be constantly active and equipped for flexible use. Along with all these conditions, safety and cost-effectiveness are also important factors. These conditions of use are the concrete equivalent of the need for energy efficiency in all business life.

Today, in the light of technological developments, manufacturers are updating themselves for energy efficiency in the automotive sector as well as in construction machinery and warehouse equipment. Among these, storage and stacking equipment produces technological solutions faster and more actively due to the more specific working areas.

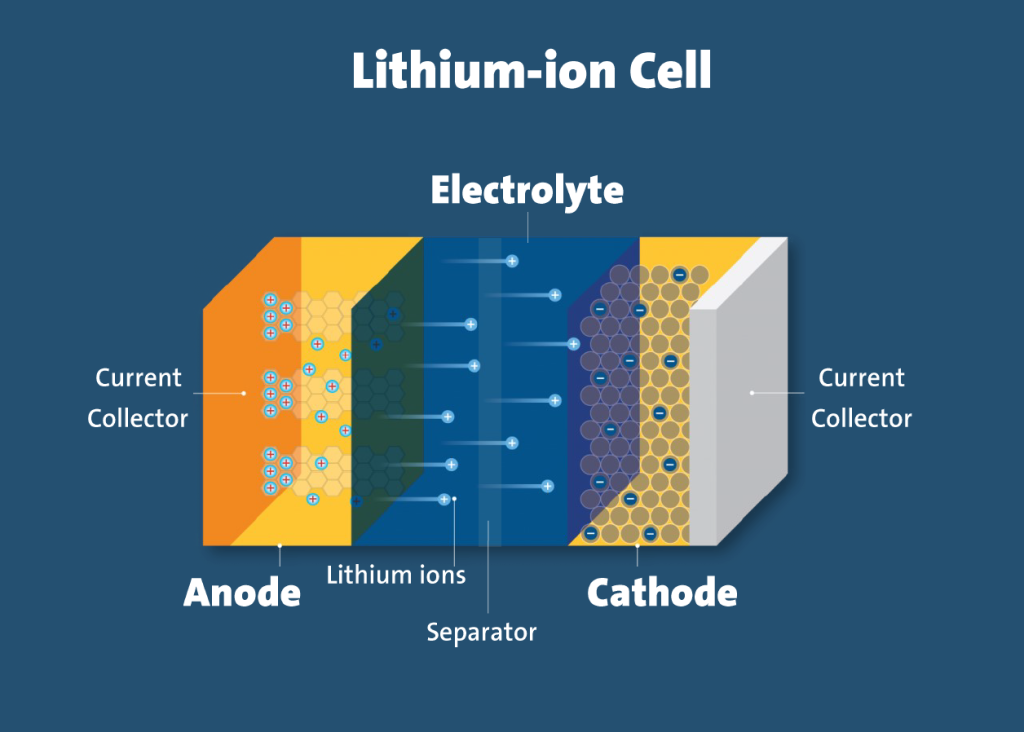

Diesel, LPG and CNG fueled equipment and forklifts are being replaced by equipment with traction batteries, and traction batteries will soon be replaced by Li Ion (lithium) batteries. Lithium batteries offer many more advantages with their fast charging, intermediate charging and efficiency in energy use. In this context, manufacturers supply the sector with titles such as direct lithium battery production, updating the traction battery machines in use as retrofit with Li-Ion technology.